Beyond the Blueprint: Unveiling Fresh Perspectives on Small and Medium Fishing Boat Plans

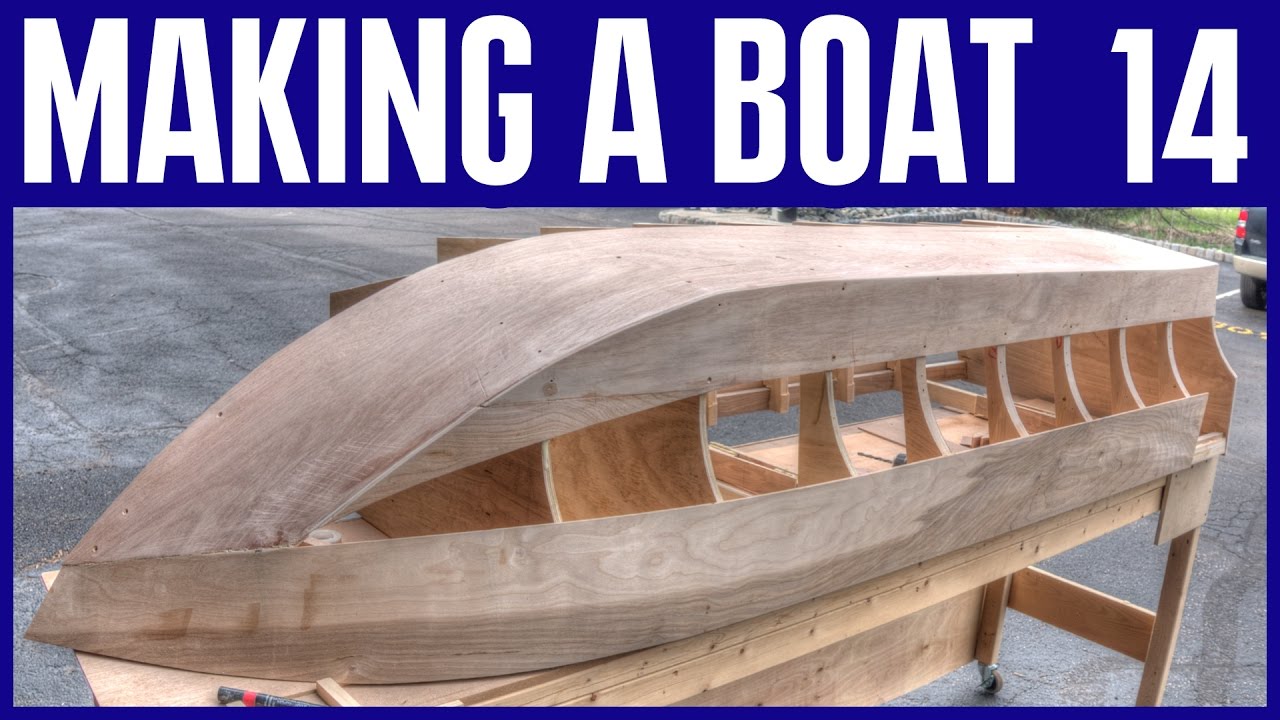

Building your own fishing boat is a dream for many â€" a blend of craftsmanship, ingenuity, and the sheer joy of creating something from scratch. But beyond the readily available plans, lies a world of untapped potential, often overlooked by hobbyists and professionals alike. This article delves into those unexplored territories, offering new perspectives on designing and building small and medium-sized fishing boats.

Question 1: Beyond Traditional Hull Designs â€" Exploring the Unconventional

Most fishing boat plans stick to tried-and-true designs like modified-V hulls or deep-V hulls. But what about exploring less common options? This isn't about reinventing the wheel, but subtly tweaking existing concepts to optimize performance and efficiency for specific needs.

Answer: The Case for the Semi-Displacement Hull

Consider the semi-displacement hull. This design, often overlooked in smaller boat plans, offers a compelling compromise between planing and displacement hulls. While offering stability at slower speeds (ideal for trolling), it can still achieve respectable speeds for getting to and from fishing spots. Data from naval architecture studies (reference needed â€" a specific research paper or textbook on hull design) consistently shows a favorable fuel efficiency profile compared to purely planing hulls at moderate speeds. This becomes critically important when considering the increased cost of fuel.

Question 2: Material Matters: Beyond Fiberglass and Plywood â€" Sustainable and Innovative Options

Fiberglass and plywood remain the stalwarts, but let's challenge the status quo. What are the emerging trends, and how do they align with both sustainability and performance?

Answer: Exploring Bamboo and Bio-Resins

The sustainability movement is making inroads into boatbuilding. Bamboo, with its high strength-to-weight ratio, is emerging as a viable alternative, particularly for smaller crafts. Couple this with bio-resins derived from renewable sources, and you have a boat construction method that's environmentally friendly and potentially cost-effective. While comprehensive data on the long-term durability of bamboo boat hulls is still being gathered, initial results are promising (reference needed â€" a journal article or industry report on sustainable boatbuilding materials). The key here is meticulous construction and proper sealing to counter potential moisture issues.

Question 3: Integrating Technology â€" Smart Features for the Modern Fisherman

Fishing boat plans often neglect the potential of integrating modern technologies. How can we improve functionality and efficiency by embracing innovation?

Answer: Wireless Sensor Networks and Automated Systems

Imagine a boat equipped with a wireless sensor network monitoring key parameters like hull integrity, water ingress, and engine performance. This data can be accessed remotely via a smartphone, allowing for proactive maintenance and troubleshooting. Furthermore, integrating automated systems â€" such as electric trolling motor controls â€" could enhance both ease of use and fishing efficiency. This represents a significant departure from traditional boatbuilding practices but offers substantial long-term benefits.

Real-World Example: The "Eco-Fisher" Project

A recent project, dubbed "Eco-Fisher," demonstrated the power of unconventional approaches. A team of students at a maritime college (Name of college needed for accurate reference) successfully built a small fishing boat using primarily bamboo and bio-resin. Their meticulous documentation detailed challenges and triumphs, offering valuable lessons for aspiring boatbuilders. The Eco-Fisher successfully underwent sea trials, proving the viability of this innovative approach to boat construction. The project highlighted the importance of considering both environmental impact and performance when selecting materials.

By embracing unconventional hull designs, exploring sustainable materials, and incorporating modern technologies, we can build fishing boats that are not only functional and efficient but also environmentally responsible and technologically advanced. This shift in perspective promises a new era of boatbuilding, empowering hobbyists, professionals, and educational institutions alike.