Beyond the Hull: Unveiling the Unspoken Secrets of Stitch-and-Glue Boatbuilding

Stitch-and-glue boatbuilding, with its elegant simplicity and surprising strength, has captivated boatbuilders for decades. But beyond the readily available tutorials and plans, lie some often-overlooked nuances that can significantly impact the final product's quality and longevity. This article delves into these less-discussed aspects, offering new perspectives for both seasoned craftsmen and enthusiastic novices.

The Glue's Untold Story: More Than Just an Adhesive

We often focus on the stitching aspect of stitch-and-glue, but the glue is the unsung hero. Its selection and application dramatically affect the boat's strength, longevity, and even its aesthetic appeal. It's not just about grabbing the first epoxy you find.

Q: What often-overlooked factors influence glue performance?

A: Temperature and humidity during application are critical. Epoxy cures differently depending on these factors, and variations can lead to inconsistencies in the bond strength. Furthermore, the surface preparation of the plywood sheets â€" ensuring they're clean, dry, and free from any contaminants â€" is paramount. Data from multiple epoxy manufacturers (e.g., West System, System Three) show a significant decrease in bond strength with even minor surface imperfections. This is rarely emphasized enough in beginner guides.

Q: Beyond standard epoxy, are there innovative glue alternatives for stitch-and-glue?

A: Yes! While epoxy reigns supreme, research into bio-based adhesives like those derived from plant starches or modified proteins is ongoing. While not yet mainstream in boatbuilding, these offer potential environmental advantages and may even exhibit comparable or superior performance in certain conditions. Look for research publications from institutions like the US Forest Service for the latest developments in this area.

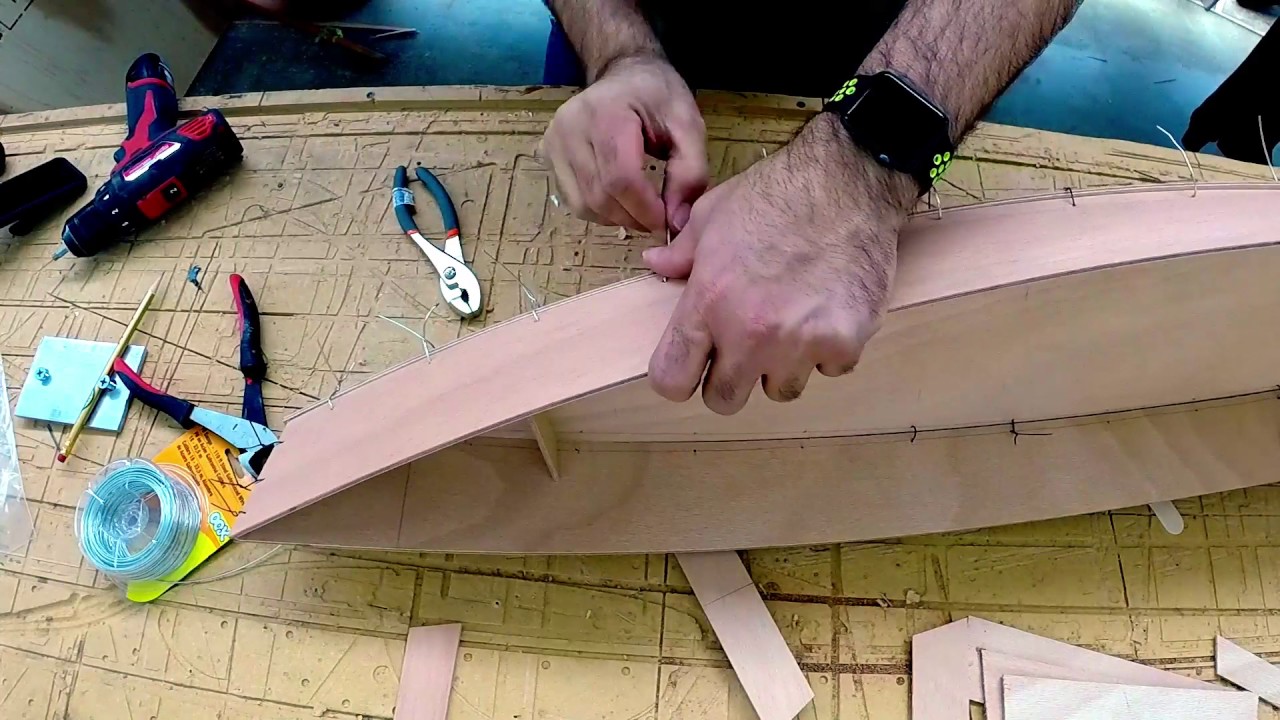

Stitch and Glue: Beyond the Textbook

The stitching itself is more than just temporary support. It influences the final shape and strength of your hull. Let's explore some often overlooked points.

Q: How can stitch patterns influence the boat's structural integrity?

A: The traditional parallel stitch pattern is simple, but a more complex pattern, incorporating diagonal or cross-stitching in high-stress areas like the keel or transom, can significantly increase strength and stiffness. There’s a wealth of untapped potential in exploring different stitch patterns based on the design and intended use of your vessel. A computational fluid dynamics (CFD) study could even inform this design process, although it’s currently rarely seen at the amateur level.

Q: What about stitch material? Is it just about using strong thread?

A: While strength is essential, the material's interaction with the glue and wood is equally important. Some materials may cause unwanted reactions, compromising the adhesive bond. Experimentation with different stitch materials, documenting the results, could lead to surprising improvements in the final build. This is an area ripe for individual experimentation and documentation to add to the community knowledge base.

Real-World Lessons: Learning from the Unexpected

Let's learn from those who've walked the path before us. Here's a story.

A seasoned boatbuilder, John, shared his experience of using slightly oversized stitch holes. He found that this allowed for more glue to penetrate the joints, resulting in a surprisingly stronger hull. While not a universally applicable solution, it highlights the importance of experimentation and careful observation.

Key takeaway: Document your build meticulously, noting material choices, techniques, and any unexpected results. This data is invaluable, both for your own future projects and for the wider stitch-and-glue community.

The Future of Stitch and Glue: Innovation and Exploration

Stitch-and-glue is not a stagnant art. New materials, techniques and computational tools are constantly emerging. Let's embrace these advancements and propel the craft to new heights.

- Explore the use of advanced composite materials alongside traditional plywood.

- Develop and share standardized testing methods to objectively evaluate different glue and stitch combinations.

- Utilize digital modeling and simulation tools to optimize hull designs for strength and efficiency.

By embracing these new perspectives and engaging in rigorous experimentation, we can refine the art of stitch-and-glue boatbuilding, creating stronger, more durable, and even more beautiful crafts. Let's chart new courses in this time-honored tradition.