Unlocking Stitch-and-Glue's Potential: Beyond the Basics

Stitch-and-glue boatbuilding offers a fantastic blend of accessibility and rewarding craftsmanship. However, many builders focus solely on the construction process, overlooking opportunities to optimize performance and efficiency. This article delves into often-overlooked aspects of stitch-and-glue, offering fresh perspectives for hobbyists, professionals, and educational institutions.

Beyond the Glue: Material Selection for Optimized Performance

While epoxy and fiberglass are staples, the choice significantly impacts the final product's performance. Let's explore some lesser-known options and their implications.

Q: Can alternative materials enhance performance beyond the traditional epoxy/fiberglass?

A: Absolutely! Consider using carbon fiber reinforcements in high-stress areas like the keel or stem. While more expensive, the increased strength-to-weight ratio can dramatically improve speed and fuel efficiency (if applicable). Research from the University of Southampton's composites lab highlights the superior stiffness of carbon fiber compared to fiberglass, making it ideal for minimizing hull flex under load. Alternatively, exploring bio-based resins opens up sustainable construction options with comparable properties, reducing environmental impact. These less-explored avenues require careful material compatibility testing, but the payoff in performance and sustainability can be significant.

Q: How does wood choice impact the boat’s overall weight and hydrodynamics?

A: The choice of plywood significantly influences weight and stiffness. Lighter, higher-grade marine plywood, while more expensive, can lead to a faster, more responsive boat. Consider using different plywood grades strategically â€" higher-grade for structural elements and lower-grade for less critical areas. This optimization balances performance and cost-effectiveness. Research papers on the mechanical properties of different plywood grades (easily accessible through databases like ScienceDirect) can provide a quantitative basis for this choice.

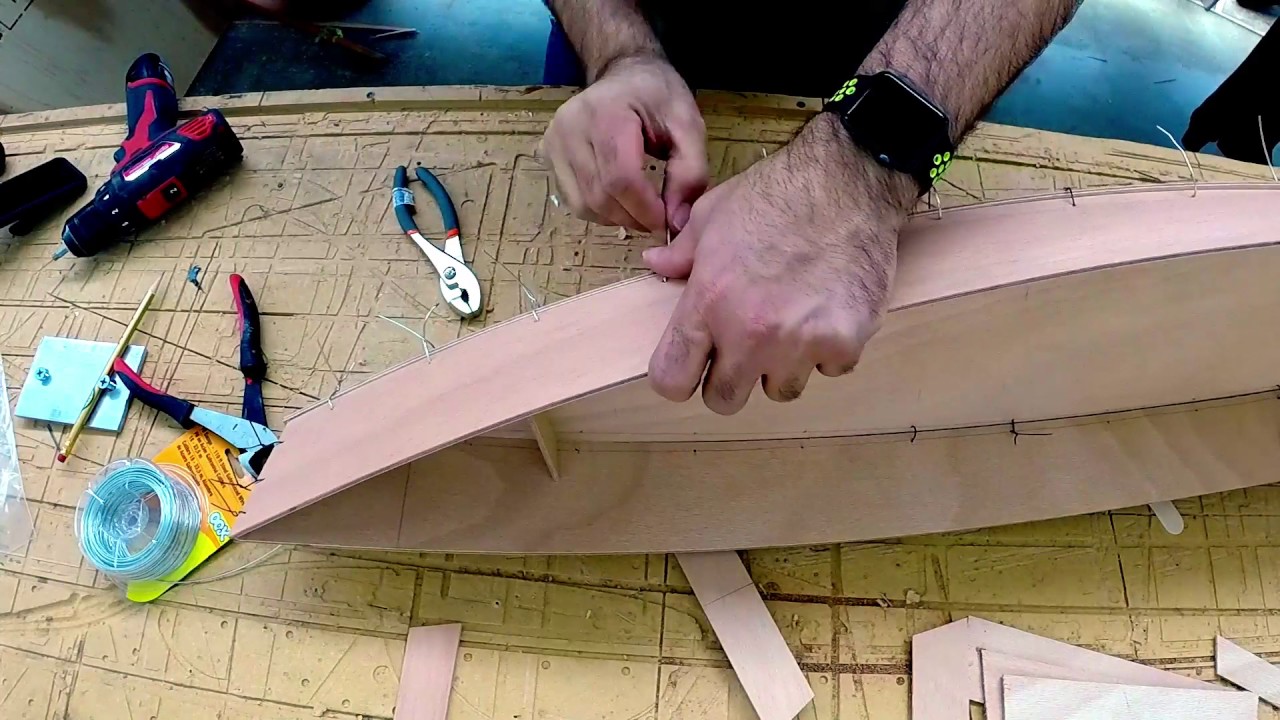

Stitching Strategies: Beyond the Basic Stitch

The seemingly simple stitching process holds hidden potential for influencing the final hull shape and stiffness.

Q: Can variations in stitch patterns enhance structural integrity or hydrodynamic properties?

A: Yes! Experimenting with stitch density and pattern â€" moving beyond simple straight lines to incorporate curves or diagonal patterns â€" can subtly alter the stiffness and even the hull's shape. While this might seem minor, it can impact the boat's hydrodynamic efficiency. Think of it as a form of pre-forming; a tightly stitched area can introduce subtle changes to the curvature, improving flow, especially in areas like the bow. This requires careful design and experimentation but offers possibilities for unique hull shapes.

Q: How can innovative stitching techniques reduce build time?

A: Consider using automated stitching tools or developing jigs to create consistent, precise stitches, which speeds up the process significantly. Also, exploring alternative stitching materials like heavy-duty thread or even thin wire can yield different strengths and potentially reduce stitching time, depending on the material's ease of handling. Documenting and sharing these techniques within the community can help others optimize their builds.

Beyond the Boat: Community and Innovation

Stitch-and-glue boatbuilding is not just about the craft itself; it's a community driven by innovation and collaboration.

Story: I recently met a boat builder who dramatically reduced his build time by designing a custom jig for automatically spacing his stitches. He then shared the plans online, fostering collaboration and accelerating progress for others. This kind of community-driven innovation is crucial.

Recommendation: Educational institutions should incorporate stitch-and-glue projects to foster design thinking and problem-solving, encouraging students to innovate beyond standard techniques and develop unique solutions for improving performance, sustainability and build time.

By pushing beyond the conventional approach, stitch-and-glue boatbuilding can become a platform for both creative design and remarkable performance. Embracing new materials, refining techniques, and fostering community innovation will unlock the full potential of this rewarding craft.

0 komentar:

Posting Komentar